Hydrogen fuel cells (HFCs) are devices that use hydrogen as a fuel to generate electricity and have great potential for automotive applications and drones. Catalysts are used to power the reactions in the HFC and currently nanotechnology plays a major role in constructing cheaper electrocatalysts.

Content

- What are hydrogen fuel cells?

- Nanoscale catalysts – Pt-dispersed on carbon nanotubes

- Nanoscale catalysts – non-precious metal (NPMCs) and metal-free catalysts (MFCs)

- Outlook on hydrogen fuel cells

What are hydrogen fuel cells? [i, ii, iii,iv]

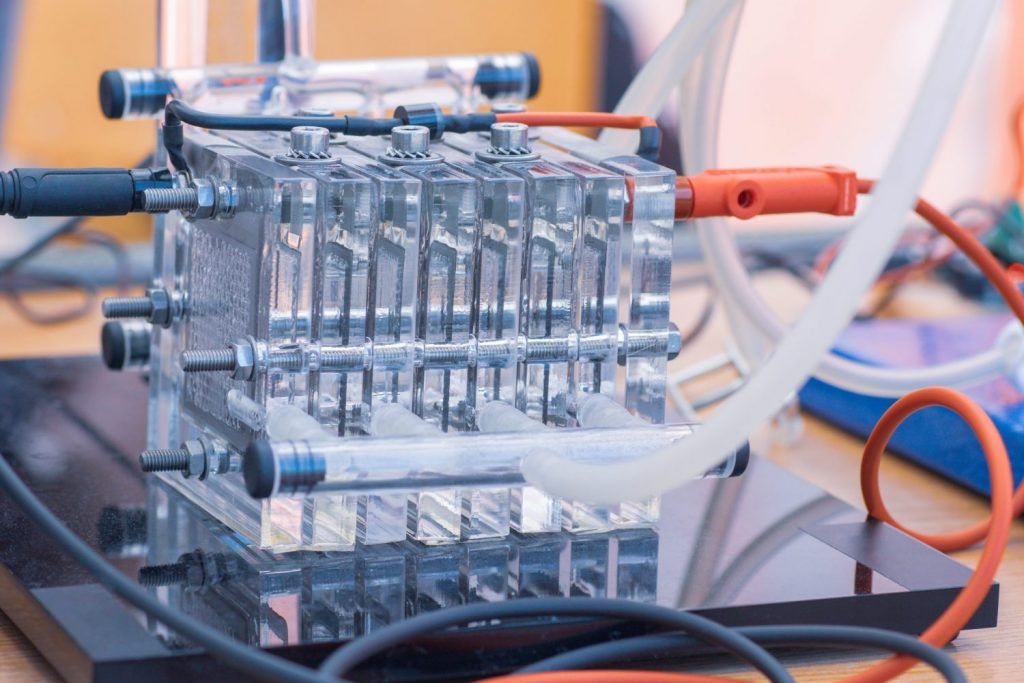

HFCs utilize hydrogen as an energy carrier to produce electricity that can be used in various applications. The HFC is an electrochemical device that converts the chemical energy in hydrogen directly to electrical energy that can be used to power a motor without combustion. This makes the HFC a very attractive replacement to combustion engines, as the HFC only emits water vapor as a waste product. What makes HFCs very advantageous in automotive applications compared to purely electrical storage is the potential high ranges. This has been applied to drones, planes, trucks, and cars

One of the most researched types of the HFC is the polymer electrolyte membrane fuel cell (PEMFC) due to its low operating temperature, very high efficiency, and low weight [i]. However, because of its low operating temperatures, the PEMFC needs a catalyst to generate useful currents due to sluggish kinetics [ii]. The most commonly used catalysts are made from platinum due to its high catalytic activity, but is expensive and of limited supply [iii], which makes it difficult for HFCs to be commercialized. Specifically, state-of-the-art platinum-based catalysts make around 25% of the overall fuel cell stack cost. [iv]

The solution to lowering costs is the use of nanotechnology. This is because most of the reactions in HFCs take place at the catalyst surface and by decreasing the size of it, you get a larger surface area per volume and therefore less material is used.

Nanoscale catalysts – Pt-dispersed on carbon nanotubes [iii, v]

One of the most promising nanotechnologies to decrease the amount of Pt is the use of multi-walled carbon nanotube-graphene complexes (MWCNTs) atomically dispersed with Pt nanoparticles, which can overall increase the performance of catalysts. [iii] CNTs are cylinder-rolled graphene sheets i.e. carbon sheets with diameters in the range of a nanometer, in which MWCNTs consist of multiple rolled layers of graphene. The MWCNTs are used as catalyst supports in this case and have excellent electron conductivity, and with its high dispersion capability and surface area, less Pt is used and the large surface area ensures a high active site density. [v]

This nanotechnology can greatly reduce the amount of Pt used in the catalyst to 0.06 mg Pt per square meters from 0.125 mg Pt per square meters, a Pt reduction of 52%! [iii] However, MWCNTs do not exclude Pt totally, but they reduce the cost greatly and this is great for the commercialization of HFCs.

Nitrogen doped on Pt-supported MWCNTs have also been introduced as a means to further increase performance by 8% in terms of maximum power density [iii], as nitrogen can enhance the properties of graphene. Additionally, there is currently research on whether Pt can be totally disregarded in catalysts, as to further reduce production costs of HFCs.

Nanoscale catalysts – non-precious metal (NPMCs) and metal-free catalysts (MFCs) [vi, vii, viii, ix]

Current and past research shows that it is possible to build non-Pt solutions, which in favor avoids the cost of platinum altogether. However, catalyst activity and stability earlier were shown to be far more inferior compared to Pt-based catalysts in terms of kinetics.

The earliest solutions utilized molecular catalysts such as iron-nitrogen complexes, but massive progress has been done with the introduction of N-doped carbon nanomaterials [vii, viii]. One of the most promising technologies is the transition metal-nitrogen-carbon catalyst due to it showing sufficient potential in durability and catalytic activity, in which iron is mostly used. [vi, vii]

However, the poor stability in PEMFC exhibits one of the greater challenges for NPMCs, which makes NPMCs not an ideal choice for PEMFCs currently. MFCs currently show interest and great promise in PEMFCs, as an N-doped CNT catalyst shows a stable PEMFC performance, though at a low activity [viii].

Outlook on hydrogen fuel cells

Hydrogen fuel cells are slowly beginning to be commercialized and with solutions to the challenges of catalyst cost, the implementation can be accelerated. There are also other challenges to fuel cells than cost that affect their commercialization and attraction, such as carbon-monoxide poisoning, high energy cost of storage, and the use of mostly fossil fuels to produce hydrogen due to electrolysis having a kinetically sluggish oxygen evolution reaction (OER) [ix] etc.

However, most of those challenges can be solved with nanotechnology, e.g. with electrolysis, the implementation of nanocatalysts can make electrolysis a more attractive option or the use of nanoparticles in photoelectrochemical water splitting can make hydrogen production more environmentally friendly [x]. While it is tempting to look at other energy options due to challenges of the HFC technology at present, the future advantages of the technology make it worth the investment in nano-solutions to solve them.

If you’d like to learn more about nanotechnology, please subscribe to our newsletter and stay tuned for upcoming posts.

References

[i] Dicks, Andrew L. Rand, David A. J.. (2018). Fuel Cell Systems Explained (3rd Edition). John Wiley & Sons. Retrieved from https://app.knovel.com/hotlink/toc/id:kpFCSEE01P/fuel-cell-systems-explained/fuel-cell-systems-explained

[ii] Chen, Yuanjun et. al (2018). Enhanced oxygen reduction with single-atomic-site iron catalysts for a zinc-air battery and hydrogen-air fuel cell. Retrieved from https://www.nature.com/articles/s41467-018-07850-2

[iii] Lou, Chong et. al (2014). A Review of the Application and Performance of Carbon Nanotubes in Fuel Cells. Retrieved from https://www.hindawi.com/journals/jnm/2015/560392/

[iv] Technische Universität Darmstadt (2020). Investigation of the degradation process of non-precious metal catalysts (NPMC) for the oxygen reduction reaction (ORR) in proton exchange membrane fuel cells (PEM-FC). https://www.mawi.tu-darmstadt.de/ekat/ekat/research_2/stabilization/index.en.jsp

[v] Gupta, Chanchal et. al (2016). Development of multiwalled carbon nanotubes platinum nanocomposite as efficient PEM fuel cell catalyst. Retrieved from https://link.springer.com/article/10.1007/s40243-015-0066-5

[vi] Shen, Yue et. al (2014). Pt Coated Vertically Aligned Carbon Nanotubes as Electrodes for Proton Exchange Membrane Fuel Cells. Retrieved from https://www.sciencedirect.com/science/article/pii/S1877705813018134

[vii] Asset, Tristan et. al (2020). Iron-Nitrogen-Carbon Catalysts for Proton Exchange Membrane Fuel Cells. Retrieved from https://www.cell.com/joule/pdf/S2542-4351(19)30587-2.pdf

[viii] Xei, Longfei et. al (2018). Zigzag carbon as efficient and stable oxygen reduction electrocatalyst for proton exchange membrane fuel cells. Retrieved from https://www.nature.com/articles/s41467-018-06279-x

[ix] Cheng, Yi et. al (2015). Advances in electrocatalysts for oxygen evolution reaction of water electrolysis-from metal oxides to carbon nanotubes. Retrieved from https://www.sciencedirect.com/science/article/pii/S1002007115001264

[x] Mao, Samuel S. (2012). Nanomaterials for renewable hydrogen production, storage and utilization. Retrieved from https://www.sciencedirect.com/science/article/pii/S1002007112001463

Great article! It’s going to be exciting to see the development of HFC technology in the coming years.